Ashford Handicrafts Ltd operates from a 3,400 square metre (36,500sq ft) factory on a two-hectare (5 acre) site located on State Highway 1, in Ashburton. This rural town is a one-hour drive from Christchurch, the main South Island city.

The historic Mill House built in 1912 is adjacent to the factory and is home to our show room, classroom, craft shop and café. It is also the centre of our Craft Village.

We use only the finest beech hardwood sourced from sustainably managed forests with Forestry Stewardship Council approval. It is stacked and allowed to air dry before kiln drying to ensure the timber remain stable. Once sawn, beech shows a beautiful colour range from the silver sap wood to the red heart timber.

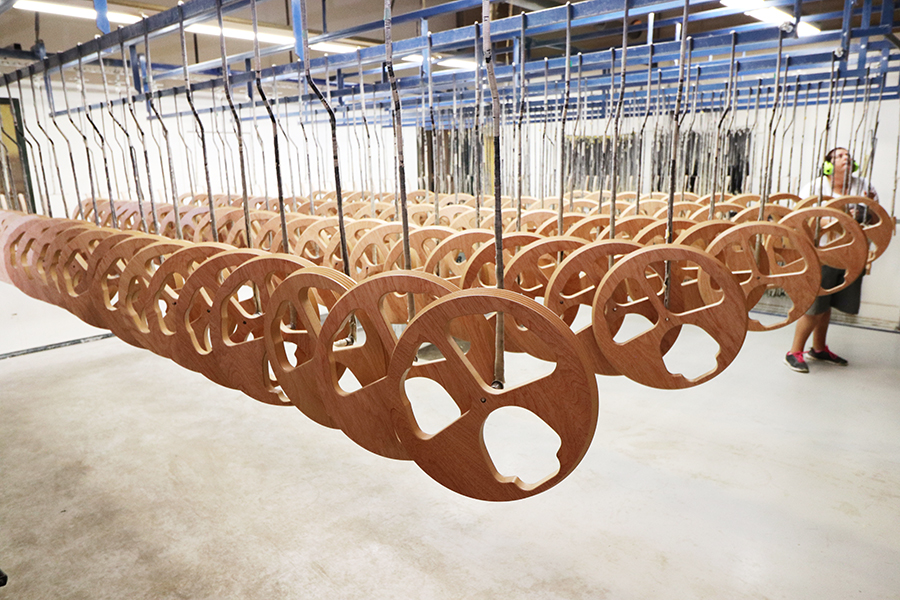

Investment in efficient CNC machinery ensures a safe work environment, high staff morale plus the ability to produce and export precision-made, affordable products to the world. Ashford products are available either natural or with a lacquered finish.

Our two dust extraction systems ensure a clean healthy environment for our staff and our wood shavings are used by local farmers. The company is active in waste reduction, recycling, energy and water conservation.